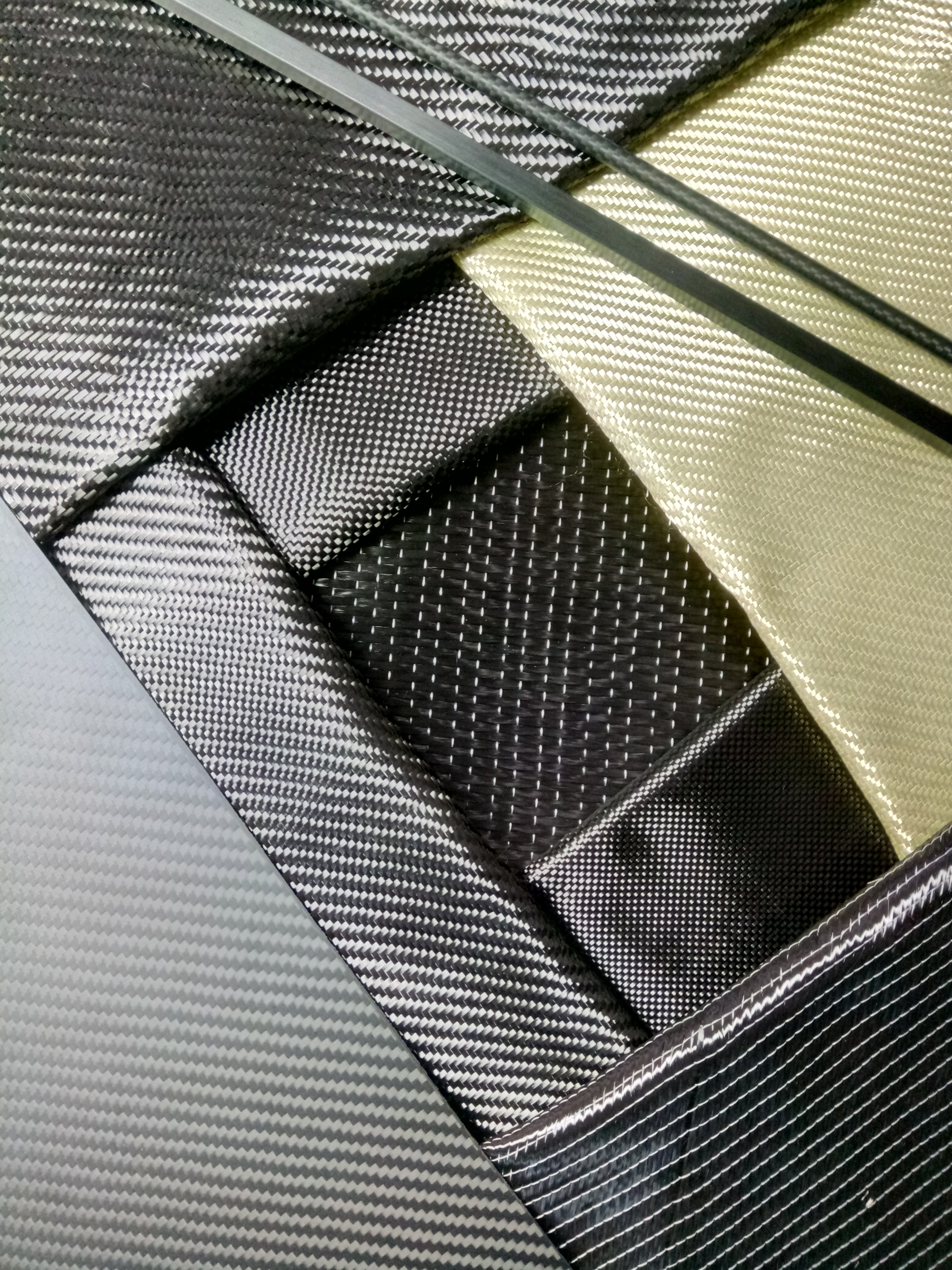

The product which arises with the combination of at least two or more materials and has new superior properties is called Composite.

As reinforcement material: Glass Fiber, Aramid Fiber and Carbon Fiber etc. available in various forms.

As matrix material: Polyester Resin, Vinylester Resin and Epoxy Resin materials are used.

In the field of composite production, we apply new raw materials and technologies together with appropriate methods and techniques, according to customer demands.

Our Composite Production Methods:

Hand lay-up: It is generally the simplest production method used. GRP (glass fiber reinforced polyester, also called Fiberglass.)

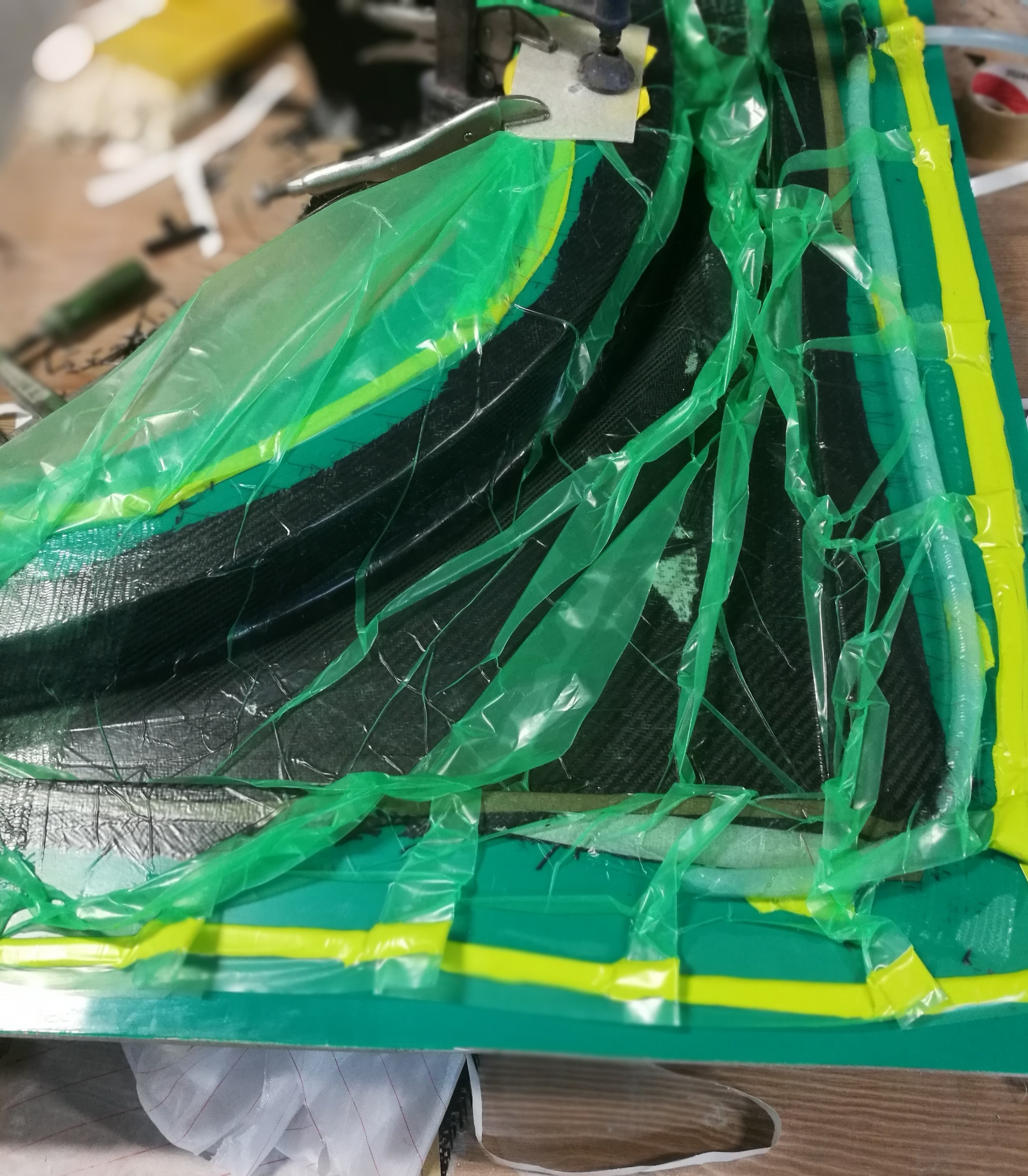

Vacuum Infusion (vacuum infusion): It is the process of laminating the resin material to the fiber material in the mold under vacuum pressure.

Vacuum Bagging: It is the process of wetting the fiber material with resin and curing it by heating it under vacuum in the oven environment.

Prepreg: It is the process of producing fiber (glass fiber, carbon fiber) material previously wetted with resin by vacuum bagging method in oven environment.

Major production areas:

Automotive

Defense & Aerospace

Construction

Health

Marine

Wind Energy

Park Garden Furniture

Decorative Products

Sports Equipment etc. It can be used in many more areas.

In BURSA since 1973

We have been serving in our Gemlik BURSA factory, which was completed in 2018, since 2019.

Quick Menu

Our services

Contact

Adress:

Umurbey mah. 5 nolu sk. No:8/1

Gemlik / BURSA Telephone: 0 224 215 12 65

Fax: 0224 215 12 66

Email: info

ayvazlar.com

ayvazlar.com 2020 AYVAZLAR LTD.ŞTİ . BURSA